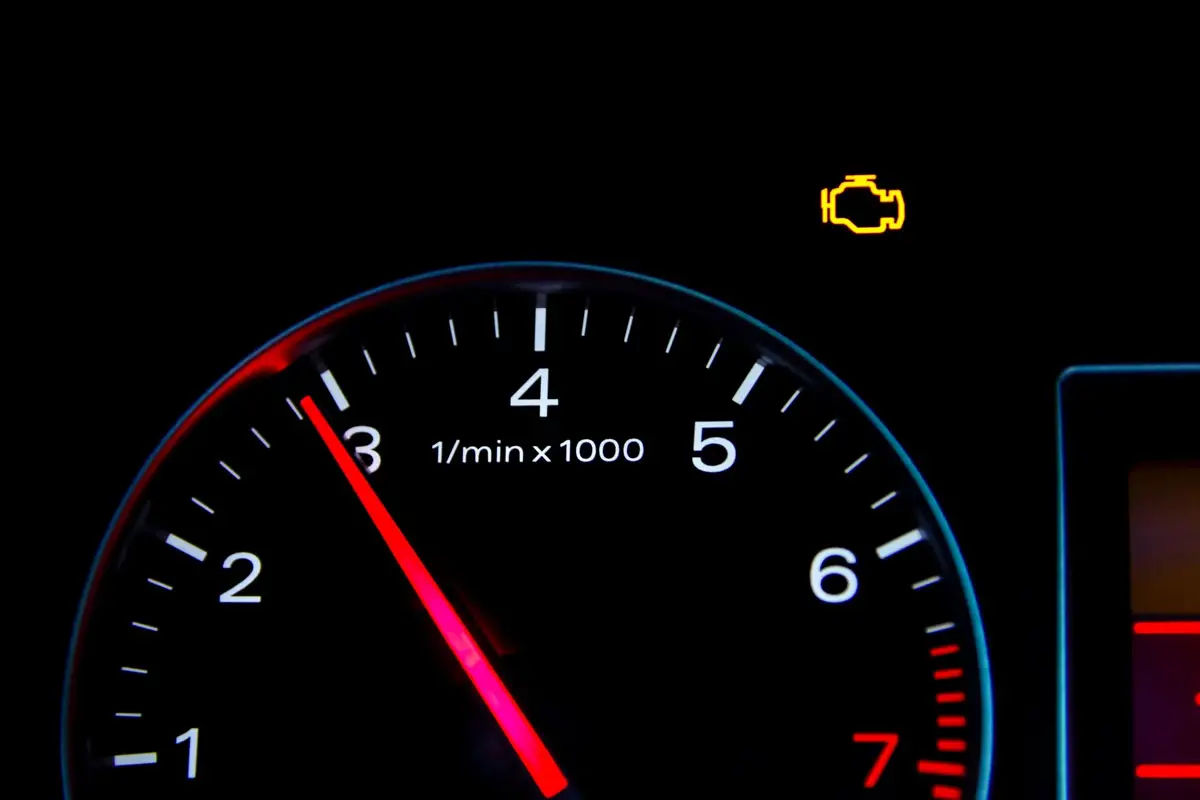

An illuminated check engine light frightens everyone. But this won’t cost you money all the time. Diagnosing the system correctly and following the specific fixing procedure can do the trick to turn the indicator light off.

In this article, we have covered all the basics about the check engine light, how to diagnose your system when the malfunction indicator light is on and some common problems with their fixes. Stay with us!

What is Check Engine Light (CEL)?

A malfunction indicator lamp, alternatively known as a check engine light, indicates there is one or more problem in your engine management system that requires your attention.

However, the light does not indicate any specific problem with the engine that you may see and fix instantly. This tiny malfunction indicator is always in front of you when you are in the driving seat. See your vehicle’s gauge cluster to find it.

Why the Check Engine Light is On?

There can be hundreds, if not thousands, of reasons behind an illuminated CEL. However, the most common reasons behind an illuminated check engine light are a clogged muffler, malfunctioning catalytic converter, or overheating of the engine due to the lack of engine oil.

Apart from these, a flashing light indicates a serious problem while an illuminated one refers to one that is not as serious as the earlier one.

How to Diagnose the Engine Problem Causing Check Engine Light

The easiest way to diagnose the problem is by using an OBD2 Scanner to read the fault code from the car computer system.

In 1996, manufacturers started using OBD codes in their car computer systems for easy and quick diagnostic of the problems. Although the system is not full proof and can’t let you know every malfunction in your car, it can give you a tremendous amount of information to start with.

Before you start diagnosing the problem, here is what you need to know about the CEL blinks or turned on-

Check engine light stays illuminated – Does not require an immediate solution. You can drive the car to the repair shop or your garage and fix the problem.

Check engine light blinks – the problem is immediate and can badly affect or damage the engine or other car components if driven. So, it needs an immediate fix.

How to Pull Engine Fault Codes from the Vehicle?

Pulling the diagnostic trouble codes, aka fault codes from the car is easy when you have an OBD2 scanner. Here is what you need to do-

Put the key in the ignition switch, and turn it to the run position to illuminate the gauge cluster. You should now see the CEL either turned on or blinking. Don’t start the engine as it will reset the light or can cause damage to the engine.

Find the OBD connection plug close to the driving seat, generally found in the lower portion of the dashboard, and plug the connector in. The connector is a 16-pin D-shaped one. So, it should not be hard for you to find.

Now, perform a scan in the OBD2 scanner to see the fault codes.

How does the OBD system work?

OBD or Onboard Diagnostic system is an integrated program in your vehicle’s computer that tracks different sensors placed all over the car to make it easy to locate problems.

However, you can’t see the diagnostic trouble codes (DTC) without using an OBD2 scanner. While the car computer system stores the DTC, aka fault codes, the OBD2 scanner pulls the data from the system to show them to you.

How to Read Diagnostic Trouble Codes (DTC)?

You may have used an OBD2 scanner tool to pull the fault codes and saw there is nothing except some codes. So, how do you translate the codes into understandable language?

The best way to do that is by using the owner’s manual of the vehicle. You should find the codes there and get a detailed idea about the issue. The fault codes start with either of these four letters, i.e. P, U, B, C

These letters indicate different parts of your car like ‘P’ indicates the problem is in your powertrain, ‘U’ for the network, ‘C’ for chassis, and ‘B’ for the body.

How to Fix Problems that Caused Check Engine Light to Turn on?

While the engine trouble codes can hint about 3 million different problems relating to your vehicle, there are some of the most common malfunctions in the engine management system that we are elaborating on here-

1. Throttle Position Sensor Fault (P0122)

The throttle position sensor, aka TPS, is a tool that ensures the delivery of the correct mixture of fuel and air to the engine. So, this is a crucial part of the fuel system that can cause serious problems if damaged.

Common symptoms of a bad throttle position sensor are poor fuel economy, rough idling, problem accelerating the vehicle, difficulty switching the gears, etc.

How to Fix a Bad Throttle Position Sensor?

The most common cause of the throttle position sensor not working is the loose connection. So, before you think about replacing the sensor, double-check the wire connectors to see whether the connector or the wire is loose or damaged.

If the wiring is all good, try resetting the sensor. To do that, disconnect the cable from the negative terminal of the car battery and leave it for five minutes. Now, reconnect the negative cable to the battery and check if the problem persists or not.

In case the problem persists, you need to replace the throttle position sensor of your vehicle.

2. Exhaust Gas Recirculation Valve Problem (P0401)

EGR valve is another key component of your car engine management system. It recirculates a small amount of exhaust to the engine combustion chamber. By doing this, decreases the combustion temperature and reduces the formation of nitrogen oxide.

A common problem with the EGR valve is that it gets clogged and becomes incapable to flow a sufficient amount of exhaust back to the engine combustion chamber.

However, this problem won’t stop your engine from running but will cause a significant drop in performance and can cause engine damage if left unattended.

How to Fix EGR Valve Problems?

In most cases, cleaning the valve will do the trick. However, if you see that the valve is worn out or not in good shape, you should consider replacing it. These are very inexpensive. Therefore, we recommend replacing the old malfunctioning EGR valve with a brand new one.

3. Crankshaft Position Sensor Malfunction (P0335)

As the name suggests, the sensor monitors crankshaft movements and signals the engine management system for injecting fuel or ignition. By using the information from the crankshaft position sensor, the engine computer system maintains the optimal timing to inject fuel.

When the sensor malfunctions, it can cause various problems. Common symptoms of a crankshaft position sensor malfunction are random stalling, the vehicle vibrating or it is getting difficult to start the engine.

How to Fix a Crankshaft Position Sensor Malfunction?

There is no fix for a bad crankshaft position sensor except replacing it. However, there might be some other issues that can cause your good crankshaft position sensor not to work properly. One of the most common of those is loose wire connections. So, check for any loose or damaged wire and the connectors.

If the connections are good and the wires are powering the sensor perfectly, you need to replace the sensor to keep your vehicle running smoothly.

4. Faulty Mass Air Flow Sensor (P0101)

One of the most common problems for which CEL turns on. The Mass airflow sensor measures the amount of air flowing to the engine. Any malfunction in this sensor gives the engine inaccurate data about the airflow and eventually, the engine management system miscalculates the airflow and injected fuel.

Symptoms of a bad mass airflow sensor include engine hiccups, engine idle or stalling, difficulty starting the engine, etc.

How to Fix a Faulty Mass Air Flow Sensor?

The mass airflow sensor is not repairable. So, the fix is to buy a new sensor and replace the old one with a new mass airflow sensor.

5. Faulty Coolant Temperature Sensor (P0118)

Another common cause of an illuminated CEL. The sensor can be damaged because of a radiator leak, broken hose, water pump failure, a broken thermostat, etc.

So, one fault code leads you to different replacements or fixes at once.

Apart from the malfunction indicator light, there are other symptoms of a faulty coolant temperature sensor. Those are- poor fuel economy, black fume coming out of the engine, and engine overheating.

How to Fix a Faulty Coolant Temperature Sensor?

Like the other one we have discussed above, there is no fix for a malfunctioning coolant temperature sensor except to replace it with a new one. The sensor is not repairable and requires a new product as soon as it gets damaged.

Final Thoughts

CEL can frighten you. It frightens everyone as most of the time they are associated with problems that require expensive repairs or replacements.

However, don’t panic when you see an illuminated light in the gauge cluster. It may be caused by a mere loose wire or a damaged inexpensive engine part. Take your OBD2 scanner and read the fault codes to see which component is causing the problem.

Finally, don’t ignore a CEL or reset it without fixing the issue. While some minor issues can cause the CEL to turn on, leaving them unattended can cost you a lot in the future.